"Titanal Boards"

This is a common term, sometimes called "boards with metal/titanal core". It can be misleading. How a board made of metal would work?

At first: Titanal is an aluminum alloy, which contains few percent of titanium. It is much closer to 1% than 10%. Titanal is used in layers with thickness most usually 0,5-2mm.

What is the difference? What titanal affect?

Mostly on transverse stiffness. And it is really major impact. And makes board like "spring".

Do not be afraid of them. Titanal boards are not stiffer than without it. And also should no be more difficult to ride. The ride should be more pleasant.

The board will have much more transverse stiffness, what will be very positive for on-edge turns on very hard snow. It will be more difficult to slide, but we are not sliding... we are carving on edge ;)

Board will have also more elasticity, so will be much more dynamic. Also will be less nervous and much more stable during the ride.

Disadvantages.

There are also disadvantages. It is durability. Titanal boards are much more sensitive to mechanical damages. Most often damage is delamination.

And it is probably only one disadvantage of titanal boards... except the price

Titanal itself is not expensive material, and the cost of used material affects the price of the board minimally. But the technology needed to assemble a layer of titanal to wood core has a quite big impact on a price.

The most difficult thing is to assembly titanal to the core of board. There are different ways to do it. Titanal can be bonded directly to the wood core by glass/carbon fiber or can be assembly on a layer of special rubber, or another material, due to tension distribution. The layer of aluminum works in a different way than wood core. More. Down titanal layer (base side) is being extended and upper (topsheet side) is being compressed when board bends.

Different manufacturers handle it different ways. For sure using titanal in snowboard is a bigger problerm than in skis, where is used the same way. But snowboard is much greater width than ski and force (torque) is applied in two places that can generate unnatural bending and twisting of a bard.

Returning to delamination topic. When board is damaged for example by hitting something , or dynamic bend during fall, small part of titanal can delaminate form core. It can be hit by skier, or pressed by binding edghe when board bended strong. From this time, every big tension could caused detach another part of titanal from core. If water will come there, the effect will be devasting, and final delamination will be only a matter of time.

Best example is top titanal layer, between sidewall ABS and topsheet. This layer is visible in all titanal boards. Every hit of anything, even your own boot, can be visible by deforming of a flat layer of titanal. Or board nose when hitting a gate...

The lower layer is hide between core, base and edge so we can not see it. But it can be visible when waxing base, when titanal is heating and characteristic convexity is visible. The delaminated part is rising up. When board cools, it is again not visible.

Fortunately properly manufactured titanal board will not delaminate itself. It is neede external stimulus for it ;)

BTW we can meet this (titanal) technology in all hi-tech manufacturers like: Kessler, Oxess, Apex, Goltes, Donek etc. rarely can be found for "mainstream" brands produced in factories. Exception is SG (Full Race and Pro Team) and F2 (proto and WorldCup).

Construction of titanal boards:

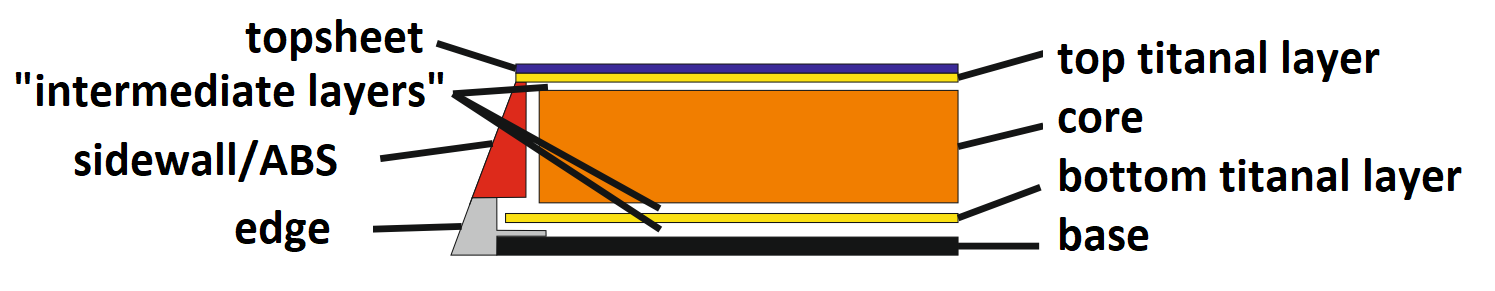

How titanal board looks inside?

From the bottom. Base, titanal, core, titanal, topsheet/base. And intermediate layers between titanal and core made of materials that depends on manufacturers philosophy and available technology.

We can point a few version/approaches of titanal boards construction

First "hi-tech" is best. Board has two layer of titanal: top and bottom, as on picture. This is most expensive version od titanal boards, but the best. It is world cup boards construction. We have few theories here. A lot of boards have symmetrical construction, from bottom: base, titanal, core, titanal and base used as topsheet, like Kessler or Goltes. For the rest of boards topsheet is not a base, but laminate like Oxess, SG or Donek. Sometimes there is no topsheet and top layer od board is just pure titanal.

Second options is only bottom layer of titanal. It also affect positively on transverse stiffness and supports edge which is very important for transverse deflection of board. But titanal is not connected directly with the edge to avoid tensions like for example temperature expansion difference between aluminium/titanal layer and steel edge. It is linked via a layer of "intermediate layer" like a special kind of rubber.

Option three is only top layer of titanal between core and topsheet. It is easier in production. And it is the layer that we can see between topsheet and ABS sidewall. Such board still has most of "full titanal" characteristics but is not the same... Less transverse stiffness, more transverse deflection because the edge is not supported by titanal layer, but straight wood core, which affects od our ride comfort when snow is very hard.

But we still have most of "titanal effect" in much better price.

Digression: In case of "mainstream" bioards sometimes manufacturer put in description "titanal". Because titanal boards are flag boards of every brand, there are top boards. But sometimes in such "mainstream allmouontain" softtboot boards cases the titanal form description is not a layer of alloy but rather something like aluminum foil with minimal thickness, which will not affect how board ride. But will affect on price, because of "titanal".

Fortunately, all alpine snowboards manufacturers are not doing this, so for us, carvers, a problem not exists. But for "mainstream" boards it is really possible.

And last option of titanal boards, can be called "Semi-titanal" boards. It is a budget version. If one of the most important titanal advantages is transverse stiffness, and transverse torsion is a problem mainly between bindings. So why not put titanal only there? If we assembly titanal layer on a top of the core only between bindings, we will have good transverse stiffness in a place of board where out technique is important but the nose and tail which are "free" of such torques will have no titanal. And effect is a board that will have quite good transverse stiffness in a good price. But such board will not be such dynamic as full-titanal board, but much better than no-titanal board.

Summary.

Titanal appears in snowboard in the mid-nineties of the last century. Every major alpine snowboard manufacturer has titanal boards in offer. For race boards, tiitanal is "must have". Dynamic, stability, smoothness of riding are main advantages of these boards, absolutely necessary for racing on gates. This characteristic is also wanted for tourist boards. But for extremecarving boards, that need to be supress, dumped not responive , titanal is not a needed element. For other boards yes.

Most of manufacturers categorizer their boards for titanal and non-titanal boards. To feel difference, as always, you just need to ride them ;)

REMARKS:

Notice that SnowboardAcademy.pl website contents only chosen aspect of snowboarding. This is not an complex publication "how to snowboarding". The authors are responsible for any individual attempts of performing descibed snowboading elements of technique or equipment adjusting.

All rights reserved. Copyrights SnowboardAdacemy.pl

This website and it content are legally protected by Polish Law, currently effective Act on Copyrights and Related Rights.

Copying and further publication of its contents without a prior author's consent and source (www.SnowboardAcademy.pl) indication is strictly forbidden.

e-mail: info@shaman-snowboard.pl

|